Filtration

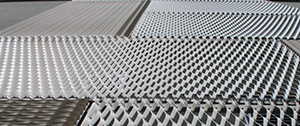

Precision expanded micro metal mesh for filtration applications is available in aluminum, stainless steel, and an extensive range of ductile metal materials and polymers. They are characterized by precision-engineered mesh openings, percent open area and mesh thickness. These material types offer physical, chemical, and thermal characteristics that are engineered specifically for filtration. Micro metal mesh provides a consistently high level of precision and strength that filtration applications require. Niles expanded metals will design the right metal mesh for your specific application whether for air, light, solid, liquid filtration, or retention.

Precision micro metal mesh can be used in filtration as support for filter media as well as to provide a first filter, thus protecting filter media from larger particles. Expanded metal mesh is easily formed into conical, corrugated, or cylindrical shapes, or left as sheet for support of filter media in automotive, chemical, food service, petroleum, and pharmaceutical applications and more.

Our metal mesh is available in sheet and coil formats in aluminum, brass, carbon steel, copper, Monel, nickel, stainless steel, titanium, precious metals, and polymer materials. Filter media support can be improved and strengthened by integrating the metal mesh into or around the media itself. Metal mesh benefits filtration applications through large open areas for strength and support to the filter media while allowing high throughput rates.

Micro metal mesh provides excellent sound absorption, reducing the decibel levels in acoustic noise reduction applications. It is used for noise dampening functions such as for mufflers. Equally, micro metal mesh is also used in microphones and loud speakers, providing protection to sensitive membranes yet allowing a uniform permeability of sound.

Micro mesh precision expanded metal for light diffusion is available in a wide range of materials characterized by precision-engineered mesh openings, percent open area and mesh thickness. The selected material types offer varying physical and thermal characteristics. Precise and consistent forming are common yet significant factors in lighting filtration applications. Micro metal mesh always provides high levels of precision and strength.

Micro metal mesh is available in many types of materials for applications related to air, gas and liquid filtration, management, and control. The material types offer varying physical, chemical, and thermal characteristics depending on your application. Precise and consistent weaving are considerable factors in ventilation and filtration control. Metal mesh for filtration provides improved levels of precision and strength in all applications. Niles Expanded Metals will work with you to design the right mesh for your specific applications, whether for air, gas, or liquid filtration or retention. Niles Expanded Metals will prepare the best solution to meet your specifications.

Niles’ metal mesh for filtration is available in aluminum, stainless steel, nickel, copper, brass, bronze, titanium, zinc and most any ferrous or non-ferrous material, including a range of ductile metals and polymers. The selected material and design is unique for your specific application such as air diffusers, noise control panels and filter media and support. Our micro metal mesh for filtration applications vary in design and material strength and thickness to benefit flow rates, support, acoustics, and other properties. For more information on our micro mesh products, visit here!