Heating Technology

The Advanced Composites Group (ACG) is a joint establishment between Niles International and Boyce Components. We develop and manufacture a suite of technologies from the best available materials using Nano-enhanced resins, films, and non-woven fabrics for efficient heating applications.

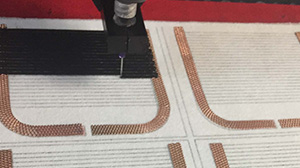

Our process combines Expanded Copper Metals Foils (ECF) as electrodes and a proprietary dispersion and blending process that combines Carbon Nano Fibers (CNF) or Carbon Nano Tubes (CNT) with any commercially available resin to make heaters to create heated surfaces, tooling, and composite structures.

Composites are a preferred material for many applications across all industries world-wide. All variations of composite products will benefit from the ability to heat internally and efficiently. Our advantage is to enable new—never before seen—heated products to be sold to the market and to improve the design and efficiency of current heaters.

We can create composite parts without the need for autoclaves by using our proprietary resin blending with Carbon Nano Tubes and Carbon Nano Fibers. The new composite manufacturing process leaves the heater within the composite part for further use in the application.

Composite materials used in aircraft wings, fuselages, nacelles and other structural parts are typically manufactured in industrial-sized autoclaves. However, The Advanced Composites Group has now developed Carbon Nano Tube (CNT) and Carbon Nano Fiber (CNF) films that can heat and solidify a composite without the need for massive autoclaves. When connected to an electrical power source and wrapped over a multilayer polymer composite, the heated film stimulates the polymer to solidify. This heating method is embedded in the finished part and can be further used to heat or de-ice the aircraft surfaces once the aircraft is assembled and in service.

In the evolution of radiant heating, every aspect of design and manufacturing has been geared toward maximizing performance. Although our patented resin blending and highly customizable designs are undergoing development and UL approval, they are soon to become the next industry-leading, low mass, radiant heating panels. Our new designs eliminate the need for standard mechanical equipment because the heat is generated—in minutes—within the pane.

We have the ability to design a heater that can fit into most applications, which allows us to supply to many different industries including transportation, infrastructure, military, green technologies, medical, telecommunications, food services, aerospace, horticulture, waterparks, pools and spas.

New and old designs are constantly improved and able to be reused with increased durability and lifespan. All composite material designs are produced to upgrade heating technology and meet safety standards. Our heating solutions are under development to provide precise, dependable and immediate heat for many different applications. Regardless of your heating application, we recommend that you discuss your requirements with our team.